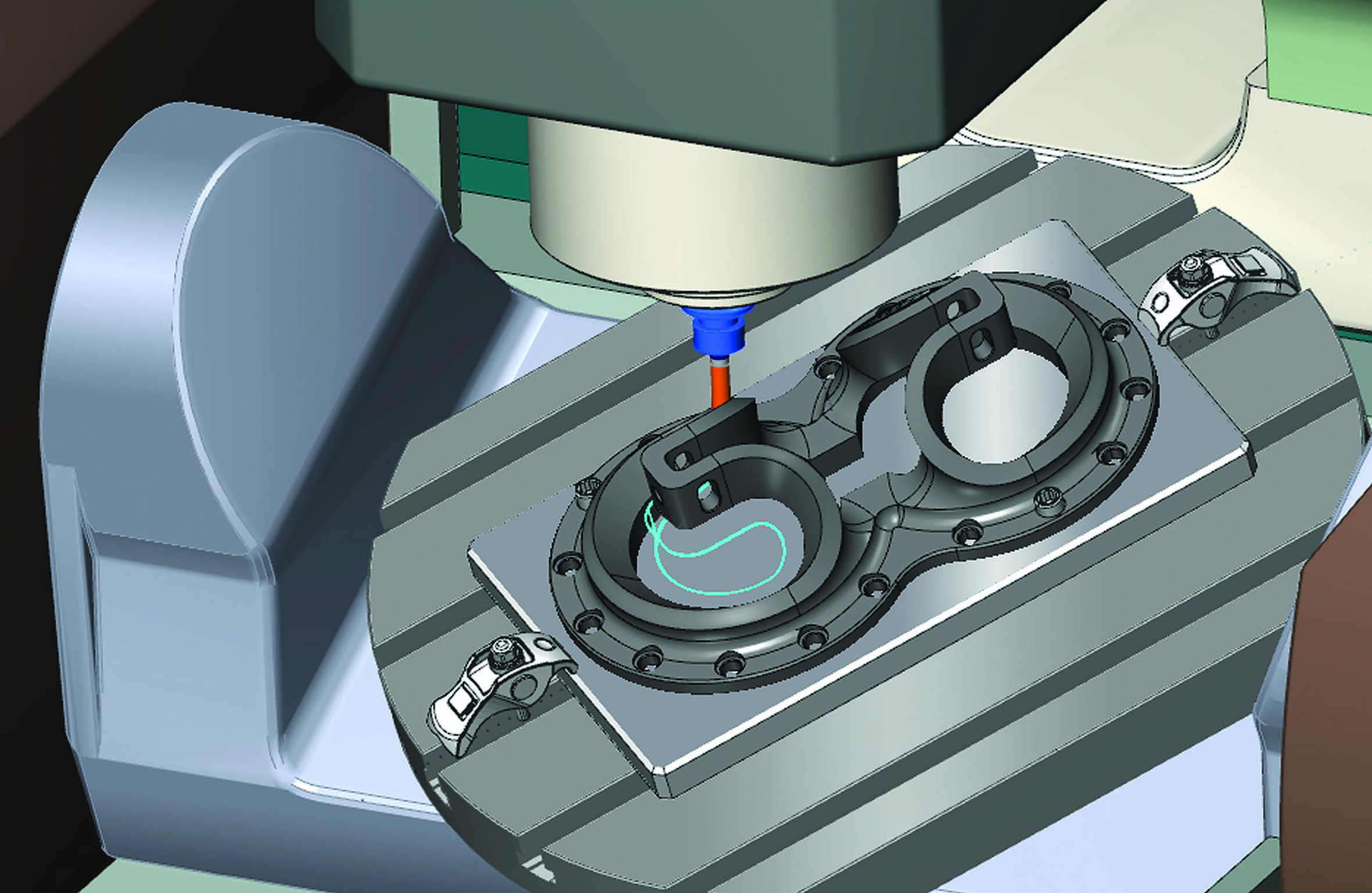

I would think that most any CNC programmer would need to now how to manipulate data, to orient it in the CAM software to work the best for how they want to manufacture a part. If you are modeling for the shop then yes model it such a way to make it easy to import/open in your CAM software. Depends on who your audience is that you are modeling for. RE: Solidworks to Mastercam SBaugh (Mechanical) 10 Dec 06 11:50ĭesign intent doesn't always work nicely with making it easy for manufacturing. I am also assuming that you could, as an alternate solution, translate/rotate the data in MasterCAM or re-oriented your WCS (Work Coordinate System) in MasterCAM to get the milling orientation you wish.ĭell Precision 380, Pentium D940, 4 Gigs RAM, FX3450 For our tool and die work this will show wire start holes, dowel/punch reliefs, etc that need to come off the CNC mill before going to the wire dept.Ĭan the newer versions of MasterCAM recognize the configurations in SolidWorks? I know Esprit 20 can. I will also add a configuration called Milling Operation which only shows the features that are needed for milling the part. I will put this as the last feature in the SW file. This will be a feature in the tree and can be suppressed or un-suppressed. Rotate the body 90 degrees so it is oriented to the xy plane in your SolidWorks file before opening in MasterCAM. Use Insert > Features > Move/Copy the body. Using a familiar platform and integrated solution, SOLIDWORKS CAM and CAMWorks bring manufacturing and design teams together, resulting in a better CNC experience all in the same interface.MasterCAM works with the xy plane as the top/plan view. CAMWorks offers several different packages, as well as additional product options and bundle add-ons. CAMWorks uses the same SOLIDWORKS geometry to generate toolpaths to ensure the part you modeled is the same part you machine. The CAMWorks portfolio offers advanced machining capabilities within SOLIDWORKS. Note: If you have a seat of SOLIDWORKS version 2018 or newer on subscription, then you already have access to SOLIDWORKS CAM. A simple upgrade to SOLIDWORKS CAM Standard or SOLIDWORKS CAM Professional unlocks additional tools such as assembly mode, 4-axis & 5-axis indexing, turning, configurations, volumill, and beyond. SOLIDWORKS CAM, powered by CAMWorks, is an integrated solution for 2.5 and simple 3-axis toolpath creation. With these developers announcing a 2024 discontinuation date of the add-in, those who rely on these combined solutions are beginning to ask themselves.now what?Īlthough the standalone MasterCAM and GibbsCAM products remain available, if you use SOLIDWORKS, there are more powerful, integrated, and native alternatives: SOLIDWORKS CAM and CAMWorks. For years, both MasterCAM and GibbsCAM offered SOLIDWORKS users the ability to use their tools in a familiar environment via the SOLIDWORKS add-in.

0 kommentar(er)

0 kommentar(er)